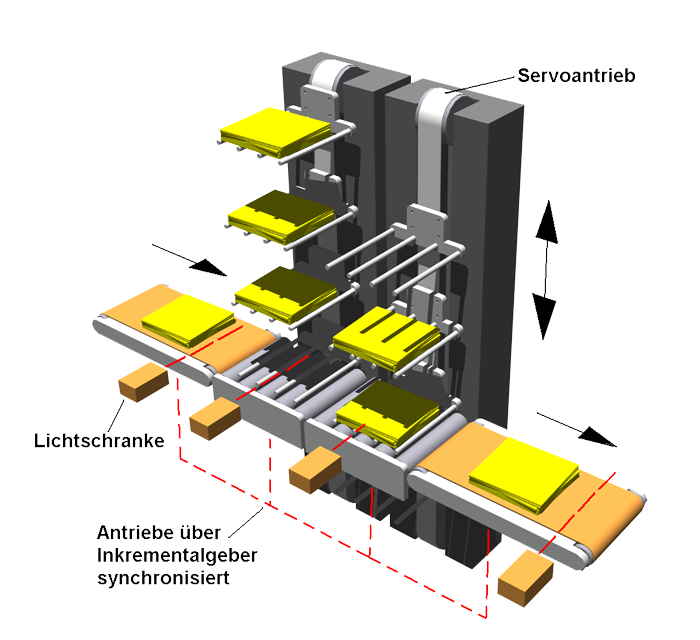

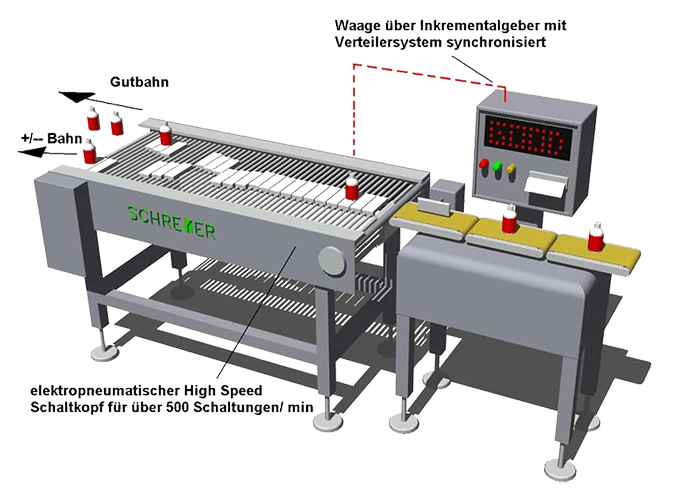

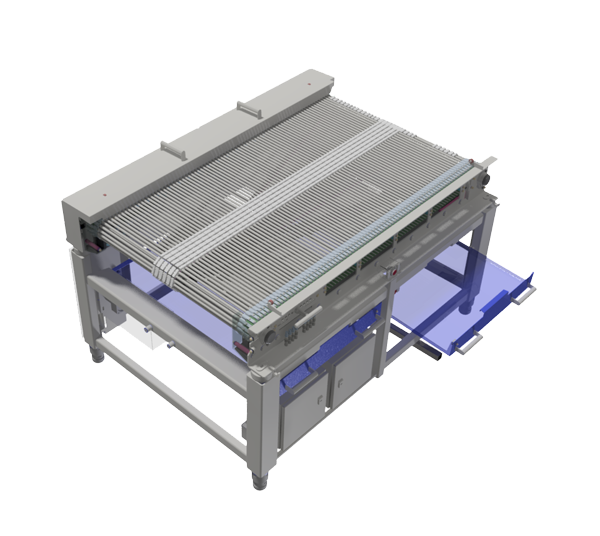

Our intelligent transport systems enable optimal production flows. The bypass, a fully equipped parallel production line, is in standby mode and steps in promptly whenever a back-up line is needed. Separation and distribution are flexibly adjusted according to the production line for reliable, ideal freezer loading at all times. Special distribution systems ensure efficient cooling gas consumption, products are prevented from freezing to each other – and at the same time the yield is increased.